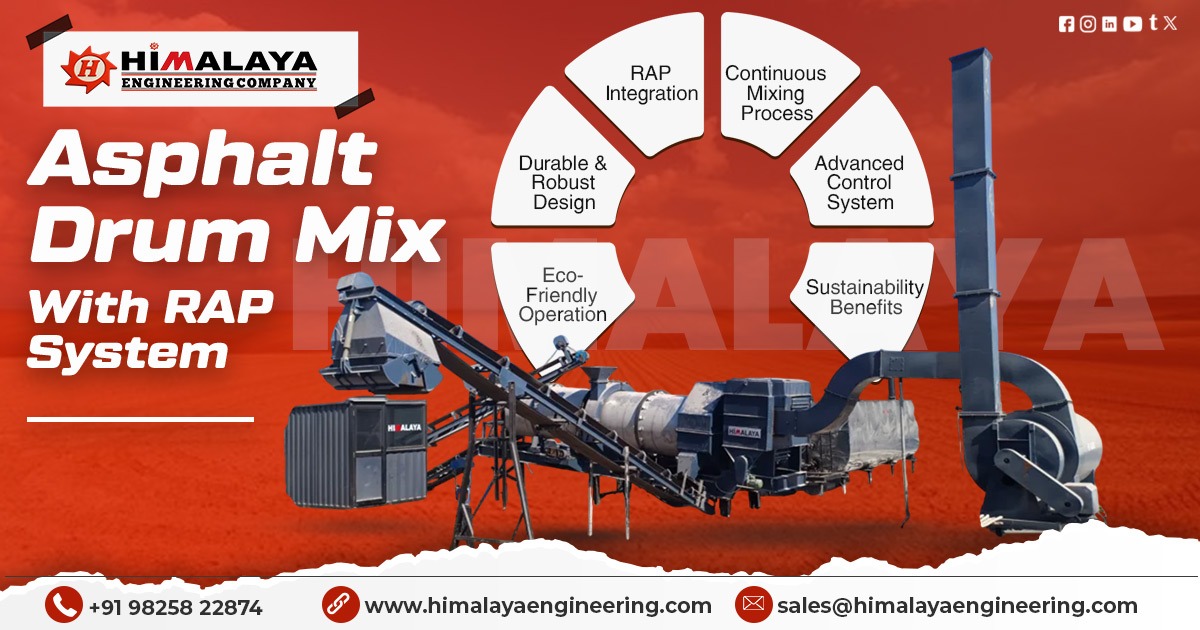

Himalaya Engineering Company offers the Asphalt Drum Mix Plant with RAP (Reclaimed Asphalt Pavement) System.

Our Manufacturing unit Is based in Mehsana, Gujarat, India.

By incorporating reclaimed asphalt, the plant reduces dependency on virgin aggregates and bitumen, lowering material costs and minimizing

environmental impact.

The continuous drum mixing process ensures uniform heating, drying, and blending of fresh and recycled materials, producing consistent asphalt

suitable for highways, urban roads, airport runways, bridges, and rehabilitation projects.

Equipped with advanced automation and robust construction, this plant provides reliable performance, operational efficiency, and flexible output

for diverse infrastructure projects.

Features of Asphalt Drum Mix Plant with RAP System

- RAP Integration: Enables the reuse of reclaimed asphalt material without compromising mix strength.

- Continuous Drum Mixing: Ensures precise heating, drying, and uniform mixing of both fresh and recycled materials.

- Advanced Control System: Computerized monitoring of temperature, mix proportions, and recycling rates for consistent asphalt quality.

- Durable & Robust Design: Built to withstand continuous operation and harsh site conditions.

- Eco-Friendly Operation: Reduces material waste, lowers carbon footprint, and enhances energy efficiency.

- Low Maintenance: Streamlined design ensures easy operation, minimal downtime, and long service life.

Specification Of Asphalt Drum Mix With RAP System

SPECIFICATION DM-35 DM-45 DM-50 DM-60 DM-65

Cap. @ 3% Moisture 45 tph 60 tph 90 tph 120 tph 150 tph

Work of Himalaya Engineering Company

Himalaya Engineering Company is a leading provider of asphalt plants and road construction equipment in Uttar Pradesh. Our team ensures:

- Professional installation, commissioning, and training for plant operators.

- Reliable after-sales service and technical support for uninterrupted operations.

- Integration of sustainable technologies like RAP to minimize environmental impact.

Applications

The Asphalt Drum Mix Plant with RAP System is suitable for:

- Highway and expressway construction

- Urban and city road projects

- Airport runways and taxiways

- Bridge and flyover deck construction

- Road rehabilitation and resurfacing projects

FAQs

Q1: What is the advantage of using RAP in asphalt production?

A: RAP reduces the need for virgin materials, lowers costs, minimizes environmental impact, and maintains high-quality asphalt performance.

Q2: Can the plant handle both fresh and recycled asphalt simultaneously?

A: Yes, the continuous drum mixing process ensures uniform heating and blending of fresh and recycled materials.

Q3: How does the advanced control system help in operations?

A: The computerized system monitors temperature, mix proportions, and recycling rates to ensure consistent and high-quality asphalt.

Q4: Is the plant suitable for large infrastructure projects?

A: The plant is ideal for highways, airports, bridges, and large-scale urban road projects.

Q5: What maintenance is required for the Asphalt Drum Mix Plant?

A: The plant is designed for low maintenance with durable components, energy-efficient systems, and easy-to-operate mechanisms.

Himalaya Engineering Company is a Supplier of Asphalt Drum Mix with RAP system in Uttar Pradesh and including locations Kanpur, Lucknow, Ghaziabad,

Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya,

Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur,

Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur,

Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj.

For more information and inquiries, feel free to contact us.

Phone No: +91 9825822874

Email Id: sales@himalayaengineering.com

Website: www.himalayaengineering.com

View Product: Click here