Himalaya Engineering Company is a trusted manufacturer and supplier of Damar Mixing Plant in Uttar Pradesh.

Our manufacturing unit is based in Ahmedabad, Gujarat, India.

Overview

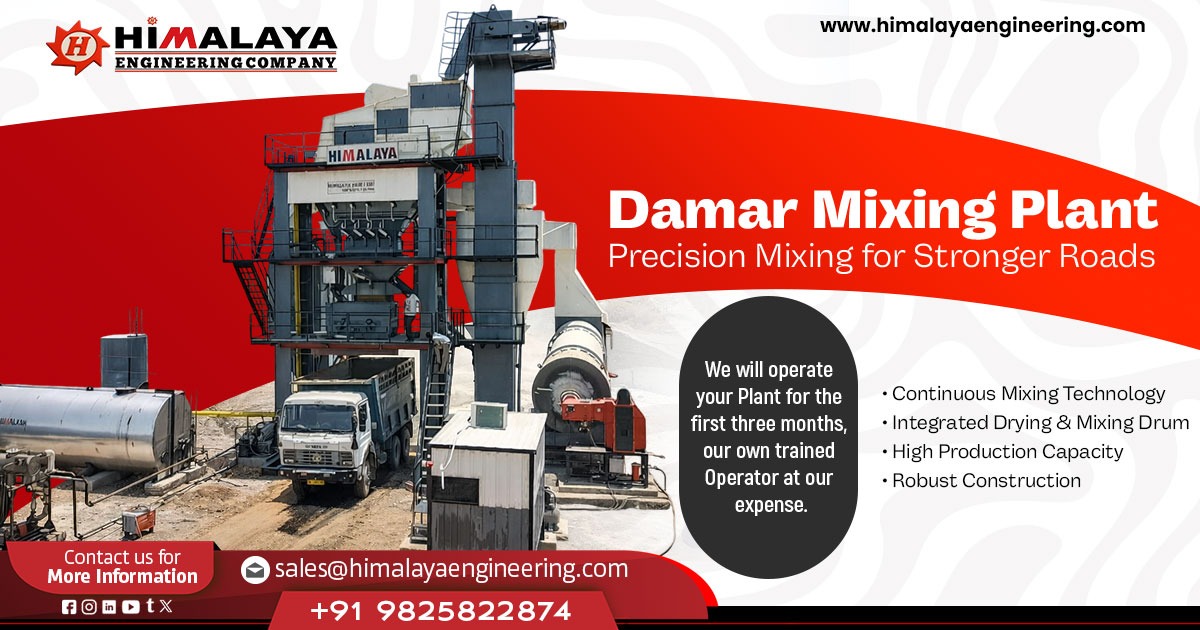

Himalaya Engineering Company offers high-performance Damar Mixing Plants in Uttar Pradesh, designed for both conventional and eco-friendly asphalt production.

Our plants are available in HBM Series and RAP (Reclaimed Asphalt Pavement) Systems, catering to projects of all sizes

— from small-scale paving works to large highway constructions.

Built for efficiency, precision, and environmental sustainability, our plants ensure smooth and reliable asphalt production.

Why Choose Our Damar Mixing Plant?

• Available in HBM Series and RAP Systems for versatile asphalt production

• High production capacity with precise mixing for consistent quality

• Fuel-efficient operation with optimized energy consumption

• Fully automated control systems for reliable and smooth functioning

• Environmentally friendly design with reduced emissions

• Trained operator support provided free for the first 3 months of plant operation

• We will operate your plant for the first three months with our own trained operator at our expense

Specification

| Model | Capacity @ 3% Moisture |

|---|---|

| HBM 1000 | 80 TPH |

| HBM 1200 | 100 TPH |

| HBM 1500 | 128 TPH |

| HBM 2000 | 160 TPH |

| HBM 2500 | 200 TPH |

| HBM 3000 | 240 TPH |

Features & Advantages

• High production capacity for small, medium, and large projects

• Precision and consistency in mixing

• Energy-efficient and fuel-saving operation

• Advanced automation for smooth operation

• Eco-friendly design with lower emissions

• Robust aggregate feeding and advanced drying system

• Efficient mixing tower for superior asphalt quality

Components of Damar Mixing Plant

• Cold Aggregate Feeder Bins

• Conveyor Belts

• Rotary Drum Dryer

• Dust Collector / Bag Filter

• Hot Aggregate Elevator

• Vibrating Screen / Hot Bins

• Aggregate & Bitumen Weighing System

• Mixing Tower / Mixer

• Bitumen Storage Tank with Heating System

• Mineral Filler Silo

• Asphalt Storage Silo / Finished Product Silo

• Control Panel / Automation System

• Fuel System

• Reclaimed Asphalt Pavement (RAP) System

Applications

• Highway, expressway, and city road construction

• Airport runways and parking areas

• Infrastructure and industrial paving projects

• Projects utilizing Reclaimed Asphalt Pavement (RAP)

• Suitable for small-scale and large-scale paving works

FAQs

Q1. What types of asphalt can the plant produce?

A: The plant can produce standard asphalt as well as eco-friendly asphalt using RAP systems.

Q2. What project sizes are supported?

A: Suitable for small, medium, and large-scale road construction projects.

Q3. Is the plant energy-efficient?

A: Yes, it is designed for fuel-efficient operation with optimized energy usage.

Q4. Do you provide operator support?

A: Yes, a trained operator will be provided free for the first 3 months of operation.

Q5. Are the plants environmentally friendly?

A: Yes, the design reduces emissions and incorporates eco-friendly features.

Service Locations in Uttar Pradesh

Himalaya Engineering Company supplies Damar Mixing Plant in cities including: Kanpur, Lucknow, Ghaziabad, Agra, Meerut, Varanasi, Prayagraj, Bareilly, Aligarh, Moradabad, Saharanpur, Gorakhpur, Noida, Firozabad, Jhansi, Muzaffarnagar, Mathura-Vrindavan, Ayodhya, Rampur, Shahjahanpur, Farrukhabad-Fatehgarh, Budaun, Maunath Bhanjan, Hapur, Etawah, Mirzapur-Vindhyachal, Bulandshahr, Sambhal, Amroha, Hardoi, Fatehpur, Raebareli, Orai, Sitapur, Bahraich, Modinagar, Unnao, Jaunpur, Lakhimpur, Hathras, Banda, Pilibhit, Barabanki, Khurja, Gonda, Mainpuri, Lalitpur, Etah, Deoria, Ghazipur, Sultanpur, Azamgarh, Bijnor, Sahaswan, Basti, Chandausi, Akbarpur, Ballia, Tanda, Greater Noida, Shikohabad, Shamli, Awagarh, Kasganj

Contact Information

Phone: +91 9825822874

Email: sales@himalayaengineering.com

Website: www.himalayaengineering.com

View Product: Click here